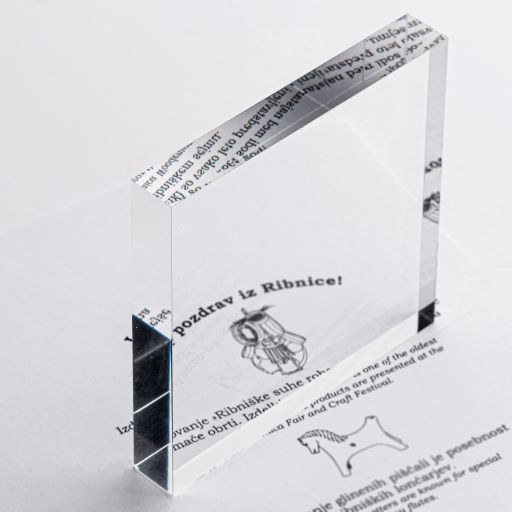

WE SHAPE PLEXIGLASS WITH OUR STYLE

Plexiglass products know no bounds when it comes to creativity, so the only limit is your imagination. A wide range of color variations, cutting, bending, gluing, engraving, and shaping sheets ensure products that you can easily combine with your interior and with wood or metal. Our experts, with years of experience in design, ensure that the products attract attention with their refined appearance.

Plexiglass products are indispensable in pharmacy, medicine, architectural equipment, gaming, food and beverage, advertising, computer, and automotive industries, as well as in interior space furnishing.

Plexiglass products do not contain toxic materials or heavy metals that could cause environmental harm or health risks and are easy to recycle.

CONSULTATION

At our company, we strive for customer satisfaction, so we provide individual attention. Based on your wishes, we advise on the selection of suitable materials (plexiglass, polycarbonate, PETG, PVC, foamed PVC, technical plastics) for the desired application. To ensure quality service, we also offer technical drawings of vector-based 2D plans.

ENDLESS DESIGN POSSIBILITIES WITH MODERN MACHINES

The variety of services we offer ensures a seamless product. The high-performance CNC machine from Protek and the laser devices from Trotec and Spirit provide extremely precise processing.

MATERIAL CUTTING

There is no need to purchase full formats, as we offer 3 different types of cutting:

- Rough cutting with a panel saw, allowing for straight cuts of acrylic glass and polycarbonate sheets.

- Laser cutting of acrylic/plexiglass allows for straight and extremely precise cuts with clean, shiny edges. Laser cutting – from simple to more complex shapes – is done according to vector plans.

Working area size: 2050 x 3050 mm

Material thickness up to 30 mm

- CNC cutting is suitable for cutting various materials (plexiglass, polycarbonate, plastic, composite sheets, aluminum, acetal, cardboard, paper, and more). In addition to basic cutting, we can also provide edge finishing, engraving, relief milling, double-sided milling, thread making, drilling, and shaping complex pieces from 2D plans.

Working area size: 2050 x 4000 mm

Maximum workpiece height is approx. 80 mm

EDGE TREATMENT

Treated edges add a touch of aesthetic perfection to the product. We are professionally trained for:

- Edge polishing on flat surfaces of various materials (plexiglass, polycarbonate, POM, PVC) from matte surfaces to high gloss, where the edges are crystal clear.

high gloss - crystal clear edges satin

- Beveling edges at an angle or radius with the option of double-sided treatment. A rounded edge gives a softer look to the item.

edges with radius double-sided edges with radius

edges at a 45° angle double-sided edges at a 45° angle

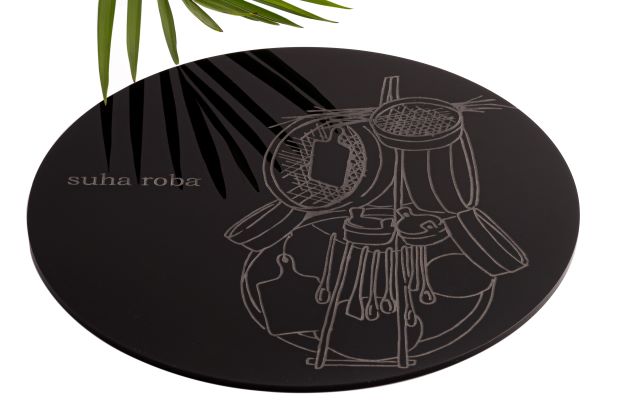

ENGRAVING

We engrave on both flat and curved surfaces.

- Laser engraving of sheets of various materials from simple texts to the most demanding graphics, including photographs up to the size of 2050 x 3050 mm.

- Laser engraving on round surfaces of plexiglass tubes and rods up to a length of 650 mm and an outer diameter of 150 mm.

BENDING or THERMAL FORMING

Complex shapes are not a barrier for us, as our team is also trained for thermoforming sheets. The company's machinery and employee knowledge enable:

- Warm linear bending of plexiglass and polycarbonate up to a length of 2050 mm and a thickness of 15 mm.

- Thermal forming according to a mold.

The radius when bending varies – depending on the thickness of the sheet.

basic radius larger radius

comparison

Bending thicker sheets.

additional processing edge grinding basic bending

comparison

MANUFACTURING

Years of searching for the right solutions in the field of gluing plexiglass and polycarbonate ensure that you will be satisfied with our products. It is worth emphasizing that we only use the highest quality and professional adhesives.

METALIZATION

This is a process in which we apply various metals under high vacuum in special airtight chambers onto transparent colored plexiglass, achieving a high gloss effect with a shiny surface. This way, we produce colored plexiglass mirrors.